Measuring bearings for your industrial application shouldn’t be difficult, but it can be easy to get confused when dealing with the wide range of bearing types and sizes available. Proper knowledge and careful attention to detail are essential to avoid mistakes and ensure the right fit for your specific needs.

If you need help with measuring bearings, Aire Bearings can help. Our team, who are expert suppliers of a wide range of industrial and manufacturing bearings, has created this helpful guide to talk you through each step to ensure you get accurate measurements for your bearings.

Common Mistakes

When it comes to measuring bearings, one of the most common mistakes is the misapplication of units—specifically, measuring metric bearings using inches and imperial bearings using millimetres. This error can lead to incorrect fitting and potential malfunction of machinery. Additionally, this mistake can result in increased wear and tear on the bearing surfaces, leading to a shorter lifespan and higher maintenance costs.

Inaccurate measurements may also cause imbalances and misalignments in the machinery, compromising operational efficiency and safety. Ensuring the correct unit of measurement is used is crucial for maintaining the integrity and performance of mechanical systems, reducing the risk of costly downtime and repairs.

Metric Bearings

Metric bearings are widely used in various applications and are characterised by their dimensions measured in millimetres. A typical metric bearing’s dimensions include the inner diameter, outside diameter, and width (also referred to as depth). For instance:

- Inner Diameter (ID): 20mm

- Outside Diameter (OD): 47mm

- Width/Depth: 14mm

These dimensions correspond to a 6204 series metric bearing. The series number often provides additional information about the bearing, such as the type and load capacity. In this case, “6204” denotes a specific bearing size and type within the metric system.

Imperial Bearings

Imperial bearings, on the other hand, are measured in inches and are commonly used in regions and industries where the imperial system is standard. The dimensions for an imperial bearing include similar measurements but are expressed in fractions of an inch. For example:

- Inner Diameter (ID): 12.7mm (equivalent to 1/2 inch)

- Outside Diameter (OD): 28.57mm (equivalent to 1-1/8 inch)

- Width/Depth: 7.87mm (equivalent to 5/16 inch)

These measurements correspond to a KLNJ1/2 series imperial bearing. The “KLNJ1/2” series denotes a specific type and size within the imperial bearing classification.

Importance of Correct Measurement

Accurate measurement is crucial for the proper functioning of bearings. Using incorrect measurements can result in:

Improper Fit: Bearings may not fit properly into their housings or onto shafts, leading to increased wear and potential failure.

Operational Inefficiencies: Misfitted bearings can cause vibrations, noise, and reduced efficiency in machinery.

Safety Risks: In critical applications, such as automotive or aerospace industries, incorrect bearing sizes can pose significant safety hazards.

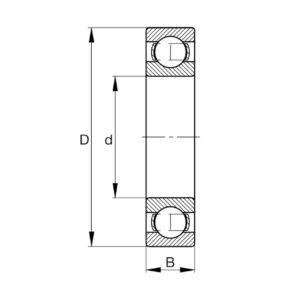

To assist you in getting an accurate measurement, there are many guides online or your manufacturer may provide a diagram to follow to achieve this. At Aire Bearings, we understand that measuring bearings when you aren’t used to doing so can seem complicated, which is why we have created a diagram to assist. See the below image for reference:

From the above, you can see you need to measure the inner diameter (d), the outer diameter (D) and the width/depth (B) of the bearing to identify it.

Tips for Accurate Measurement

Getting an accurate measurement shouldn’t be too difficult so long as you measure properly. To avoid these issues, follow these tips:

Use the Right Tools: Employ callipers designed for the unit system you’re working with.

Double-Check Units: Always verify that you are using the correct units for the bearing type—millimetres for metric and inches for imperial.

Consult Manufacturer Specifications: Refer to the bearing manufacturer’s specifications for accurate dimensions and series information.

Educate Your Team: Ensure that all team members are aware of the differences between metric and imperial bearings and the importance of accurate measurement.

By understanding and correctly applying the appropriate measurement units for bearings, you can ensure proper fit and function, enhancing the reliability and lifespan of your machinery.

Need Your Bearings Measuring? Let Us Help!

Get it right the first time and contact the team at Aire Bearings now! We can help you measure your bearings to ensure no mistakes are made, and as expert suppliers of a wide range of different bearings, including deep groove ball bearings, angular contact bearings, taper roller bearings, and more, we’re highly knowledgeable when it comes to a variety of bearing types. Get in touch now for more information.